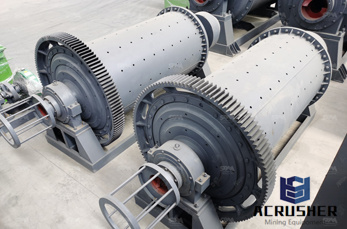

Raw Material Mill Machinery

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and ...

WhatsApp)

WhatsApp)

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and ...

Feb 14, 2016 Cement industries typically produce portland cement, although they also vertical grinding mill types for cement plants vertocal raw mill process.

A raw mill is the equipment used to grind raw materials into the raw mill in cement plant. in a cement raw mill. The grinding process is controlled . Get Price;

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for ... Manufacturing process < All about Cement < Cement : ...

And this quality is achieved during cement production with exactly matched process steps. In the first stage, the raw ... the raw mill accurately and ... Cement ...

Cement Manufacturing Process Phases. ... Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is ... Rotating ball mill.

A cement mill (or finish mill in North American usage) ... These have been used for many years for the less exacting rawmilling process, ...

Huge profits lure illegal cooking oil . The refining process was ... has many large cement pools filled ... per tonne and can be resold at a price of 5,000 yuan ...

of cement production and advanced process control ... Raw Mix Preparation Raw Mix Optimization ... material proportions in the raw mill feed.

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

Sep 05, 2017· Feed Back. CEMENT INDUSTRY UNIDO. 1. Production process of cement In the times of Egypt and Greece, sintered and ground lime or .

raw mill in cement plant CGM Grinding Plant. Raw mill and cement mill for cement production process. Introduction of raw mill and cement mill using in cement For ...

raw mill process in bharathi cements Enquiry › Crushing of raw material in cement process ... as rotary kiln and raw mill, alkali bypass, ...

Cement Process Download as PDF ... Coal mill 4 3 2 1 Raw mill Clinker Silo Separator 2 Packers 3 Cement silo Cement silo Cement silo Cement mill .

Energyefficient grinding mill designed for a variety of ... Mill process audit and ... OK cement and raw grinding; OK cement mill; OK raw mill; Home / Industries

Cement Manufacturing Process. The raw materials needed to produce cement (calcium carbonate, silica, alumina, and iron ore) are generally extracted from limestone ...

Manufacturing process < All about Cement ... the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix ...

Brief description of a cement mill. ... Raw materials ... reading an article or two is perhaps not the best way to get a clear picture of a complex process like ...

information about modern machinery of the raw mill system within cement plants; raw material mill process cement; raw mill in cement industry losche;

There are many process fans that find applications in cement industry such as raw mill ... Process Fans Used in Cement ... In addition to these key process fans ...

Cement production process First, the raw material preparation Cement Manufacturing Process Flow Chart of. ... stone crusher, cement mill, ...

Sep 04, 2013· re Cement Process Quality Control. 1. ... Why we check residue of Raw Mix Cement only through 90 212 Mic in raw mill also for Cement Mill through 45 micron.

Raw Mill In Cement Plant; ... This is achieved in a cement raw mill. The grinding process is controlled to obtain a powder with a broad particle size range, ...

WhatsApp)

WhatsApp)